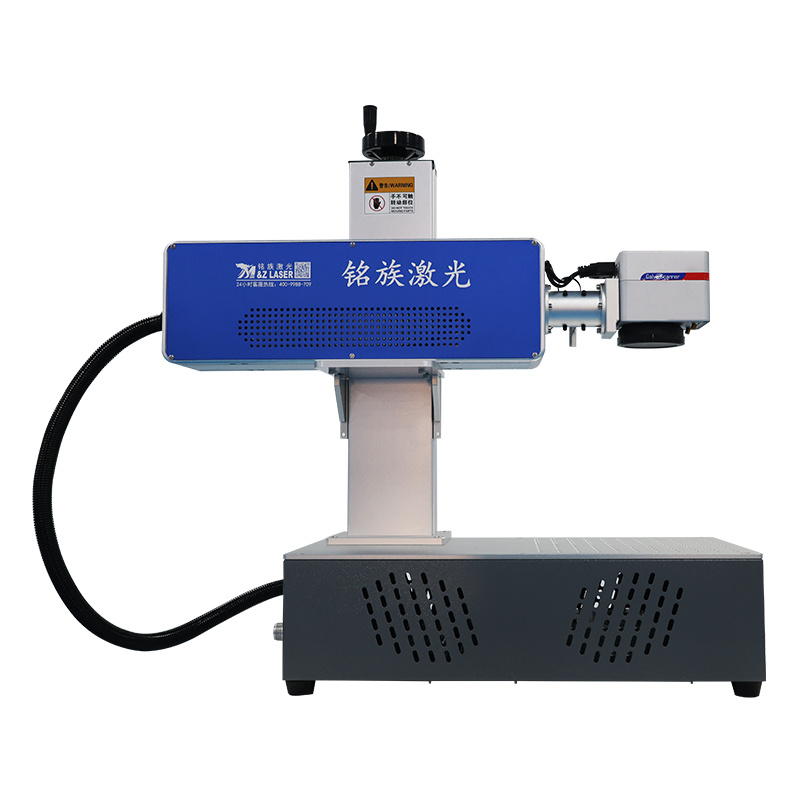

Desktop Laser Marking Machine: Principles and Applications Analysis

Release time:

2025-01-03

Desktop laser marking machines are advanced laser devices widely used in various industries and fields. They use laser beams to mark permanent labels on the surfaces of different materials, featuring high precision, high efficiency, and strong flexibility. This article will detail the working principle, performance indicators, and application range of desktop laser marking machines to help readers better understand and apply this technology.

1. Working Principle of Desktop Laser Marking Machines

The working principle of desktop laser marking machines is based on the physical process of laser interaction with materials. The laser beam has a high energy density, and when it irradiates the surface of the material being processed, the material surface absorbs the laser energy. Depending on the energy density, this process can be divided into "thermal processing" and "cold processing."

1. Thermal Processing Principle

Thermal processing refers to the process where a laser beam with a high energy density generates thermal excitation on the surface of the material being processed, causing the temperature of the material surface (or coating) to rise, resulting in phenomena such as phase change, melting, ablation, and evaporation. This process is similar to traditional thermal treatment processes but offers higher precision and controllability.

2. Cold Processing Principle

Cold processing refers to the process where high-energy (ultraviolet) photons break chemical bonds in the material (especially organic materials) or surrounding media, leading to non-thermal destructive processes. This cold processing method does not produce thermal damage side effects and does not cause heating or thermal deformation in the inner layers and nearby areas of the processed surface, thus having unique application advantages on certain special materials.

2. Performance Indicators of Desktop Laser Marking Machines

The performance indicators of desktop laser marking machines are important parameters for measuring their performance, mainly including laser mode, laser wavelength, laser repetition frequency, laser power, marking range, working power supply, cooling method, etc.

1. Laser Mode and Wavelength

Desktop laser marking machines typically use TEM (fundamental mode) laser mode, with a laser wavelength of 1064nm. This wavelength of laser has good absorption and penetration in various materials, making it suitable for most marking applications.

2. Laser Repetition Frequency and Power

Laser repetition frequency refers to the number of laser pulses per unit time, usually between 20kHz and 100kHz. Laser power determines the energy level of the laser beam, with common desktop laser marking machine powers being 5W, 10W, 15W, 20W, 30W, etc. Different combinations of power and repetition frequency can meet the needs of different materials and marking requirements.

3. Marking Range and Working Power Supply

The marking range of desktop laser marking machines is usually between 70mm×70mm and 100mm×100mm, and can be adjusted according to actual needs. The working power supply is generally 220V/50Hz/2kVA, ensuring stable operation of the equipment.

4. Cooling Method

Desktop laser marking machines typically use forced air cooling to ensure the stable operation of the laser and the entire machine.

3. Application Range of Desktop Laser Marking Machines

Desktop laser marking machines are widely used in various industries and fields, including but not limited to electronic components, communication equipment, automotive and motorcycle parts, instruments and meters, aerospace, military products, hardware machinery, sanitary ware, pharmaceuticals, food and beverages, cosmetics, drug packaging, and medical devices.

1. Electronic Components and Communication Equipment

In the field of electronic components and communication equipment, desktop laser marking machines can be used to mark information such as brand, model, and serial number, achieving product traceability and anti-counterfeiting.

2. Automotive and Motorcycle Parts

In the field of automotive and motorcycle parts, desktop laser marking machines can be used to mark information such as part names, specifications, and production dates, improving product recognition and traceability.

3. Hardware Machinery and Sanitary Ware

In the field of hardware machinery and sanitary ware, desktop laser marking machines can be used to engrave patterns, trademarks, and text, enhancing the aesthetics and added value of products.

4. Pharmaceuticals and Food and Beverages

In the field of pharmaceuticals and food and beverages, desktop laser marking machines can be used to mark information such as production dates, expiration dates, and batch numbers.