Can 2000W laser welding machine be used for thick plate welding? How is the welding effect?

Release time:

2024-09-26

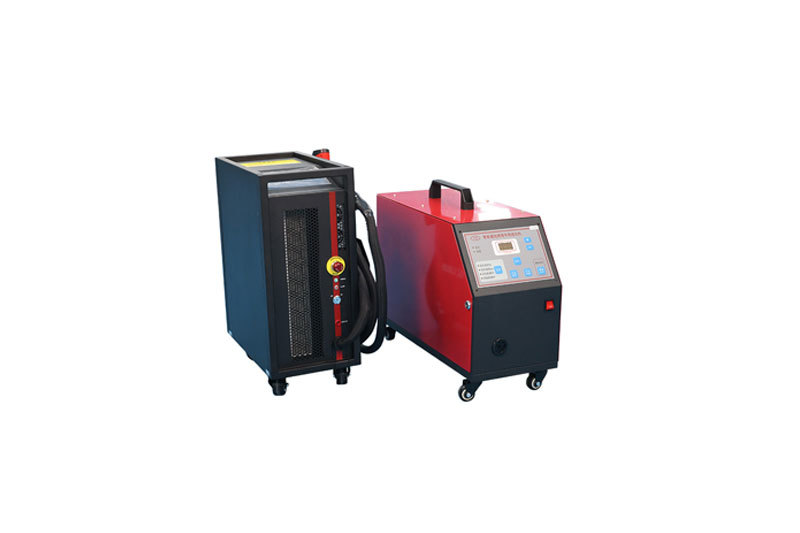

Laser welding technology has been widely used in industrial manufacturing for its high efficiency, precision and flexibility. In particular, the 2000W laser welding machine, because of its moderate power, has become a popular choice for welding thin plates and medium thickness materials. However, when many users consider using a 2000W laser welding machine to weld thick plates, they often wonder whether the welding effect can meet the expected requirements. This paper will discuss the application of 2000W laser welding machine in thick plate welding and its welding effect.

Basic performance of 2. 2000W laser welding machine

The 2000W laser welding machine usually has a high laser energy output, which can provide enough heat to melt the metal material and form a strong welded joint. Its main advantages include:

- Fast welding speedLaser welding is usually faster than traditional welding methods and can improve production efficiency.

- High welding precision: The laser beam has strong focusing ability, can realize fine welding, and is suitable for welding complex shapes and thin-walled structures.

- small heat affected zone: The heat-affected area produced by laser welding is relatively small, which reduces material deformation and thermal damage.

The challenge of 3. thick plate welding

Although the 2000W laser welding machine has the above advantages, there are still some challenges in thick plate welding:

- Insufficient heat input: For thicker materials, the power of 2000W may not be enough to generate enough heat during the welding process, resulting in insufficient welding.

- WELDING DEFECTSWhen welding thick plates, defects such as pores, inclusions and welding cracks are prone to occur, which affect the welding quality.

- Material Selection Restrictions: Different materials have different laser absorption capabilities, and some thick materials may not be suitable for 2000W laser welding.

Application of 4. 2000W Laser Welding Machine in Thick Plate Welding

Despite the above challenges, the 2000W laser welding machine can still achieve good welding results in thick plate welding in the following ways:

- Layered welding: For thicker materials, the method of layered welding can be adopted, that is, thickening welding layer by layer to ensure the penetration rate of each layer of weld.

- Adjust welding parameters: According to the thickness and type of material, optimize the laser power, welding speed and focus position to ensure reasonable heat input during welding.

- Auxiliary heating: Preheating the material before welding can reduce the thermal stress in the welding process and improve the welding quality.

Evaluation of 5. welding effect

Through appropriate technical means, 2000W laser welding machine can achieve better welding effect in thick plate welding. The strength, crack resistance and corrosion resistance of welded joints can meet certain standards. Specifically:

- welding strength: After reasonable welding process and parameter adjustment, the strength of the welded joint can reach 70%-90% of the base metal.

- Welding appearance: The appearance of the weld is smooth and neat, and the heat affected zone is relatively small, which can meet the high appearance requirements.

- low defect rateBy optimizing the welding process, the frequency of defects such as pores and inclusions can be greatly reduced, and the welding quality is stable.

In summary, although the 2000W laser welding machine faces certain challenges in thick plate welding, it can still achieve good welding results through reasonable process design and parameter adjustment. With the development of laser technology and the continuous optimization of welding technology, the application potential of 2000W laser welding machine in thick plate welding will be broader in the future, bringing more possibilities for industrial manufacturing.