-

About UsEstablished in 2010, it is the first independent laser brand in Qingdao to integrate research and development, production, and sales of laser equipment.

КонтактыТелефон службы:+86-400-9988-709

КонтактыТелефон службы:+86-400-9988-709

Почтовый ящик:Leo@qdmingzu.com

Почтовый ящик:Info@qdmingzu.com

Адрес:улица Янъян, 97, район Ченьян, Циндао -

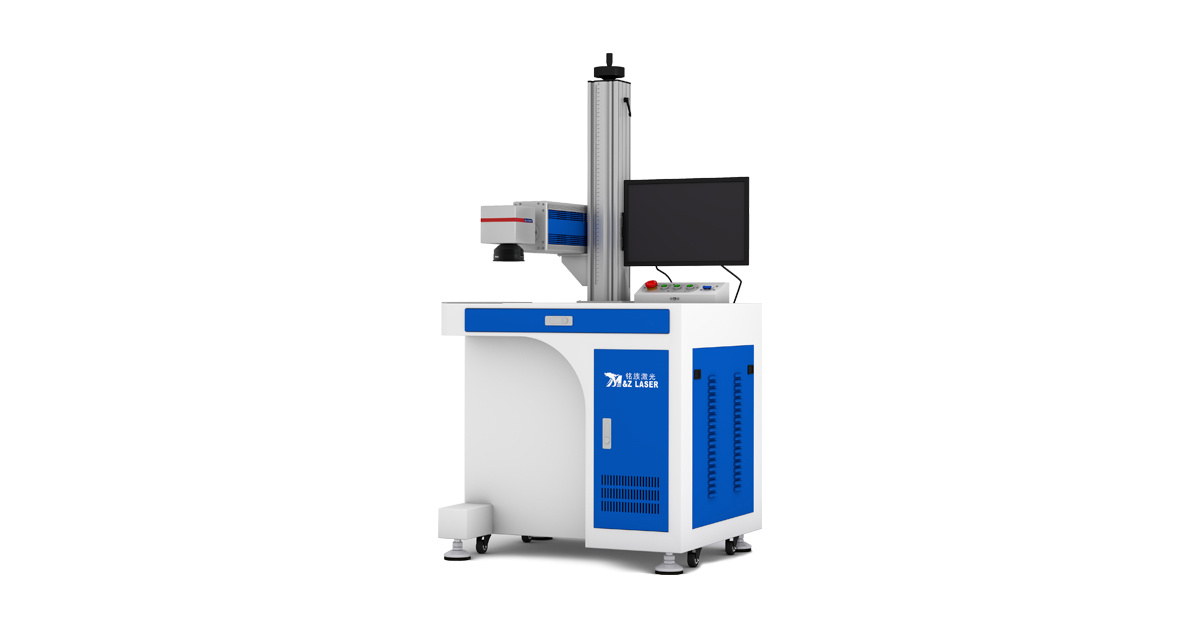

ProductsEstablished in 2010, it is the first independent laser brand in Qingdao to integrate research and development, production, and sales of laser equipment.

КонтактыТелефон службы:+86-400-9988-709

КонтактыТелефон службы:+86-400-9988-709

Почтовый ящик:Leo@qdmingzu.com

Почтовый ящик:Info@qdmingzu.com

Адрес:улица Янъян, 97, район Ченьян, Циндао -

Case CenterEstablished in 2010, it is the first independent laser brand in Qingdao to integrate research and development, production, and sales of laser equipment.

КонтактыТелефон службы:+86-400-9988-709

КонтактыТелефон службы:+86-400-9988-709

Почтовый ящик:Leo@qdmingzu.com

Почтовый ящик:Info@qdmingzu.com

Адрес:улица Янъян, 97, район Ченьян, Циндао -

TechnicalEstablished in 2010, it is the first independent laser brand in Qingdao to integrate research and development, production, and sales of laser equipment.

КонтактыТелефон службы:+86-400-9988-709

КонтактыТелефон службы:+86-400-9988-709

Почтовый ящик:Leo@qdmingzu.com

Почтовый ящик:Info@qdmingzu.com

Адрес:улица Янъян, 97, район Ченьян, Циндао -

NewsEstablished in 2010, it is the first independent laser brand in Qingdao to integrate research and development, production, and sales of laser equipment.

КонтактыТелефон службы:+86-400-9988-709

КонтактыТелефон службы:+86-400-9988-709

Почтовый ящик:Leo@qdmingzu.com

Почтовый ящик:Info@qdmingzu.com

Адрес:улица Янъян, 97, район Ченьян, Циндао

What materials can laser marking process?

Release time:

2024-08-02

As a high-precision, non-contact marking method, laser marking technology is widely used in industrial and commercial fields. It can handle a wide variety of materials, including but not limited to the following categories:

Metal Materials

The laser marking machine has strong adaptability to various metal materials, such as stainless steel, aluminum alloy, copper, titanium and its alloys. Metallic materials are often capable of producing clear, long-lasting markings on the surface, suitable for marking and traceability needs in industrial manufacturing, aerospace and other fields.

Plastic material

Plastic materials such as ABS, polyurethane, polypropylene, etc., are also often processed by laser marking technology. The laser can produce fine marks on the plastic surface by adjusting the power and focal length, which is suitable for marking and information tracking in the fields of electronic products and medical devices.

ceramic material

Ceramic materials such as ceramic tiles, ceramic surface coatings, etc., can also be marked and etched by laser marking machines. This method can achieve highly clear identification while keeping the surface of the material flat, which is commonly used in architectural decoration and handicraft manufacturing.

Glass material

Although glass is a transparent material, laser marking technology can also mark its surface. This marking method is often used in glassware, optical devices and other fields, and can achieve high-precision marking of tiny characters, patterns or barcodes.

organic material

The laser marking machine can also process various organic materials, including wood, paper, cloth, etc. These materials are often used in the art, furniture, packaging industry and other fields, laser technology can be engraved on the surface of the detailed pattern or text.

Other special materials

In addition to the above common materials, laser marking technology can also handle some special materials, such as leather, rubber, stone and so on. These materials are often used in areas such as customized products and personalized gifts, where laser marking can achieve a high degree of personalization and precision requirements.

In summary, laser marking technology has a wide range of applicability and can handle many different types of materials. With the advancement of technology and the expansion of application scenarios, the role of laser marking machines in industrial production, artistic creation and commercial applications will become more and more important.

Tiktok QR code

Service Phone:+86-400-9988-709

Address: No.97 YanYang Road, ChengYang District, Qingdao City

COPYRIGHT © 2023 MINGZU LASER TECH CO.,LTD ALL RIGHTS RESERVED